Splice Molding

Splice molding is a process used in the manufacturing of rubber products, such as belts, hoses, and seals. It involves joining two or more sections of rubber material to create a longer or more complex shape.

The process begins by preparing the rubber material by cutting it to the appropriate length and shape. The ends of each section are then shaped with a specific profile, such as a V-shape or angled cut, to create a “splice” that will fit together seamlessly.

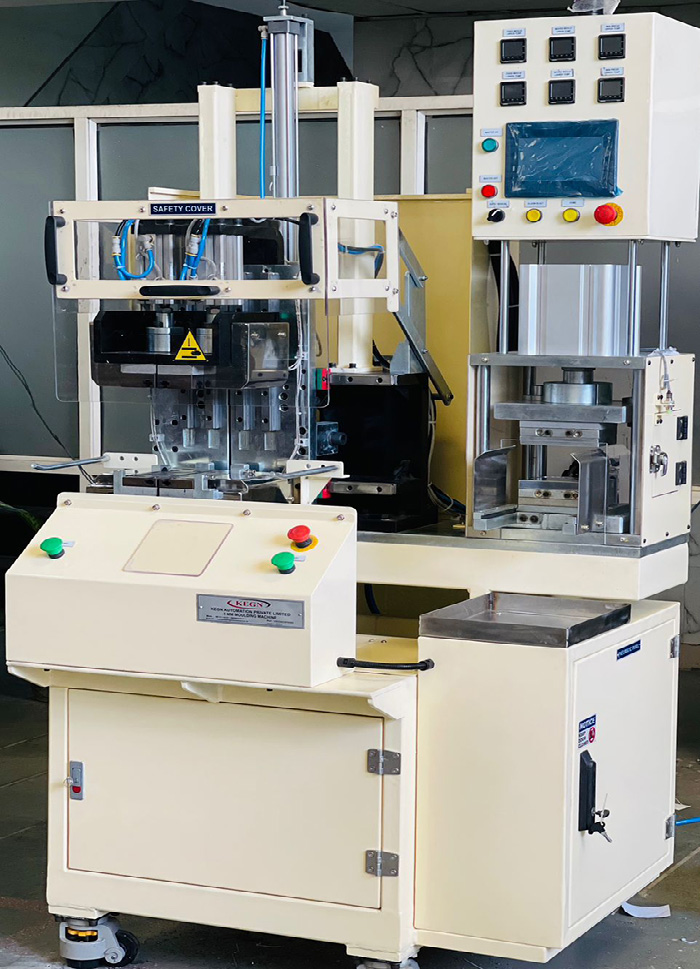

Next, the splice surfaces are coated with a specialized adhesive, which is allowed to dry. The sections are then aligned and pressed together, creating a strong bond between the materials. This process can be done manually or with the use of specialized splicing machines.