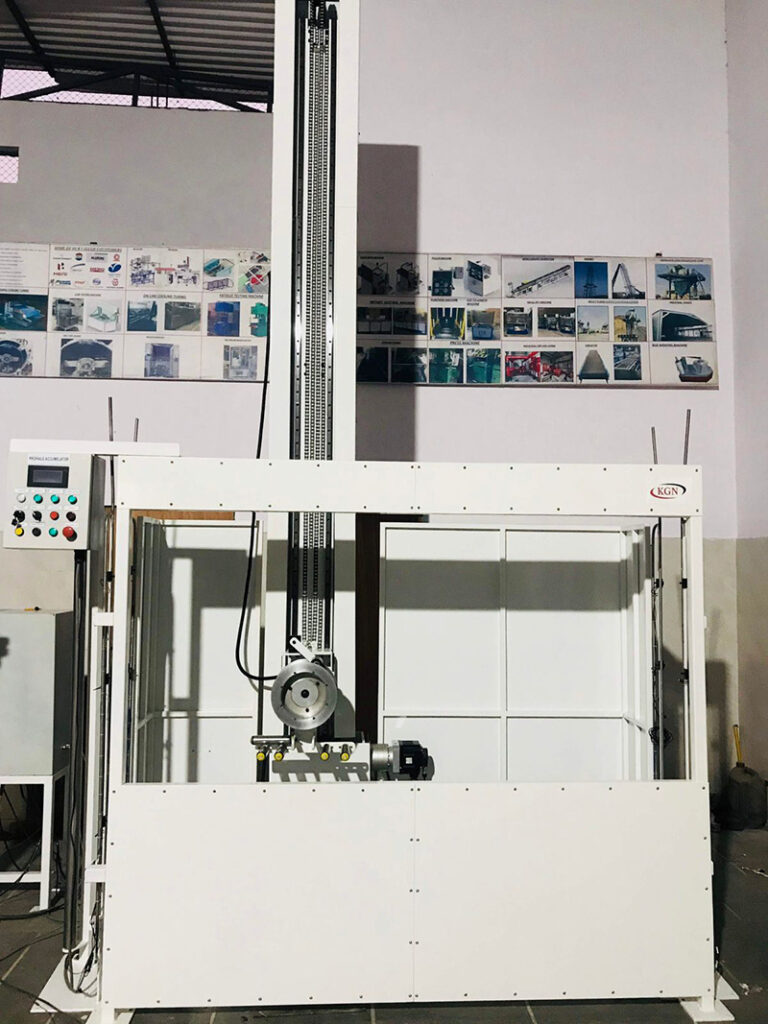

Strip Accumulator

A strip accumulator is a device used in metal strip processing industries such as steel mills and aluminum plants. It is designed to store and accumulate strip material, enabling continuous operation of the processing equipment downstream.

The strip accumulator works by collecting the incoming strip material from the upstream processing line and temporarily storing it in a loop. As the strip is fed into the accumulator, it forms a loop that is supported by a series of rollers or wheels. The accumulator can be designed to accumulate the strip in a vertical or horizontal configuration, depending on the specific application.

The stored strip material can then be released at a controlled rate to feed into downstream processing equipment, such as a roll-forming machine or a slitting line. This enables the processing equipment to operate continuously, even when there are disruptions or interruptions in the upstream supply of strip material.

Strip accumulators are critical components in metal processing lines, helping to improve productivity, reduce downtime, and optimize the use of material. They are available in a range of sizes and configurations to suit different applications and can be customized to meet specific requirements.