Profile

About us

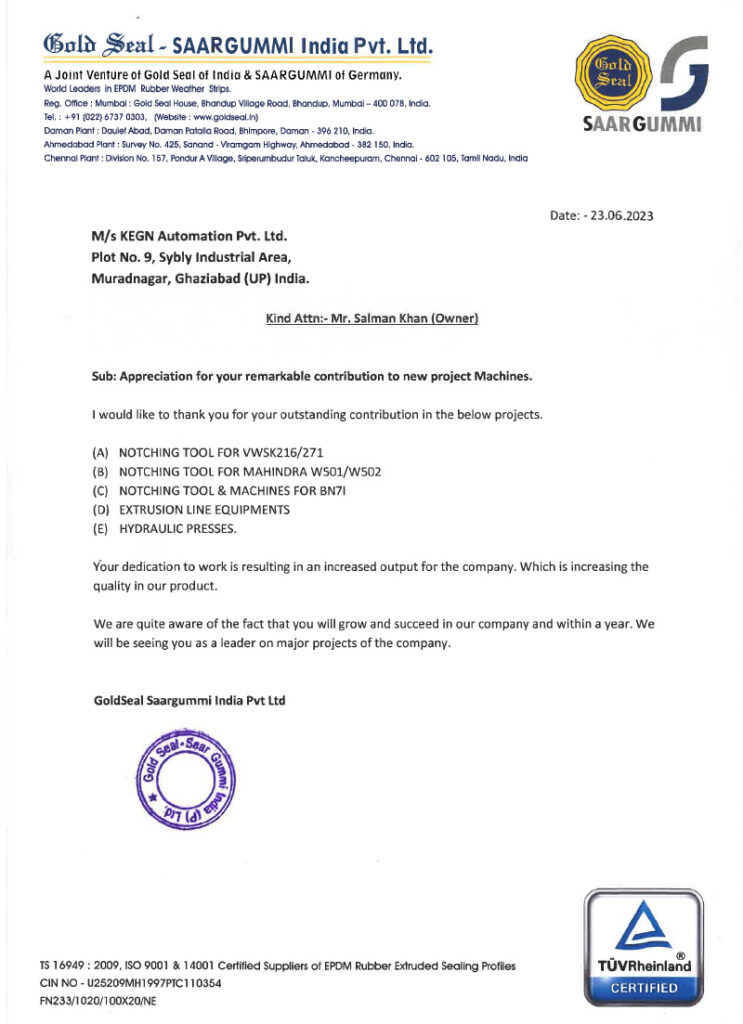

KEGN Automation are the manufactures of the widest range of downstream extrusion equipment available to the plastic, rubber, and composite industries. Our complete line of standard equipment offerings include: calibration equipment, cooling systems, pullers, in-line cut-to-length, surface finishing, coiling and fabrication equipment and end of line material handling. In addition to individual line components KEGN AUTOMATION also provides engineered, turn-key, extrusion lines including tooling, run-in, set-up supervision, start-up/ training including complete line control and integration.

From our inception KEGN AUTOMATION has been recognized as an industry leader in the manufacture of innovative extrusion processing equipment. This long history of innovation has provided numerous industry advancements particularly in the areas of precision cut-to-length technology and in-line fabrication. In addition to our full line of standard downstream equipment KEGN AUTOMATION’s large, in-house engineering staff can provide custom equipment to meet the demands of the most challenging processing requirements. This spirit of innovation and vast experience, gained in over twenty years in the downstream extrusion industry are applied to every machine we produce. Our engineering and programming capabilities allow us to provide equipment to be user and maintenance friendly, while providing long term, trouble free operation and repeatability.

Director’s Message

Salim Khan who started this company with his vast practical experience in Automation Industry, wishes to deliver the best solutions to OEM globally at an affordable price and to create an Ethical and Healthy Environment for Country, Employees, Customers and Society.

Why Us

Pre-engineering

Your process needs and requirements are documented in a joint effort with our Sales and Engineering teams. Together we create a blueprint for the ideal solution for all your packaging needs.

Installation & Commissioning

The technical construction and QA/QC of your packaging line are completed. In the next step, our certified mechanics install your new solution and commission it together with your on-site operators and other staff.

Project Management

To deliver your automated packaging solution on time and compliant with the specifications agreed upon, our Project Management Department expertly manages your project.

Training & Documentation

Operator proficiency helps you to optimally utilize the potential of your new packaging line. We provide for training and reinforcement of knowledge and skills with extensive and comprehensible documentation.

Maintenance & Updates

All KEGN Automation is designed to minimize maintenance needs. By updating functionalities and performance over time, we help you to extend the lifecycle of your solution.

Parts & Materials

Downtime is expensive and must always be solved quickly. KEGN maintains a stock of OEM components, to solve any malfunction you might experience quickly and professionally.

Vision and Mission

To embrace this intention, we developed a “CHIP” to reflect our core values. As everything we do evolves around our integrated CHIP, it stands as Commitment-Honesty-Innovation-Passion. This represents our commitment to our customers with utmost honesty that is backed by our Passion for Innovation.

Our Integrated CHIP

Our world is always rapidly evolving, and our customers expect nothing but the latest and the best. At KEGN, we embrace flexibility, in our solutions and our attitudes. This enables us to create true and lasting value for our customers. At KEGN, we are absolutely passionate about innovation. It adds the fun and inspiration to our work that people need to excel. Our customers stimulate our innovation by developing new needs, and we ourselves are on a never-ending quest to find a better, simpler way.

Once a customer entrusts us with their needs, we never want to let them go. We value long-term relations, as they reap the most benefits for everyone involved. Partners look out for each other and enable mutual success. At KEGN, the customer always comes first, to extend our partnership even beyond our joint horizon.